Page 22 - catalogo

P. 22

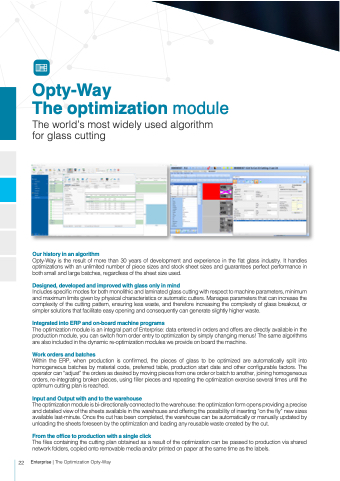

Opty-Way

The optimization module

The world’s most widely used algorithm for glass cutting

Our history in an algorithm

Opty-Way is the result of more than 30 years of development and experience in the flat glass industry. It handles optimizations with an unlimited number of piece sizes and stock sheet sizes and guarantees perfect performance in both small and large batches, regardless of the sheet size used.

Includes specific modes for both monolithic and laminated glass cutting with respect to machine parameters, minimum and maximum limits given by physical characteristics or automatic cutters. Manages parameters that can increase the complexity of the cutting pattern, ensuring less waste, and therefore increasing the complexity of glass breakout, or simpler solutions that facilitate easy opening and consequently can generate slightly higher waste.

The optimization module is an integral part of Enterprise: data entered in orders and offers are directly available in the production module, you can switch from order entry to optimization by simply changing menus! The same algorithms are also included in the dynamic re-optimization modules we provide on board the machine.

Within the ERP, when production is confirmed, the pieces of glass to be optimized are automatically split into homogeneous batches by material code, preferred table, production start date and other configurable factors. The operator can “adjust” the orders as desired by moving pieces from one order or batch to another, joining homogeneous orders, re-integrating broken pieces, using filler pieces and repeating the optimization exercise several times until the optimum cutting plan is reached.

The optimization module is bi-directionally connected to the warehouse: the optimization form opens providing a precise and detailed view of the sheets available in the warehouse and offering the possibility of inserting “on the fly” new sizes available last-minute. Once the cut has been completed, the warehouse can be automatically or manually updated by unloading the sheets foreseen by the optimization and loading any reusable waste created by the cut.

Designed, developed and improved with glass only in mind

Integrated into ERP and on-board machine programs

Work orders and batches

Input and Output with and to the warehouse

From the office to production with a single click

The files containing the cutting plan obtained as a result of the optimization can be passed to production via shared network folders, copied onto removable media and/or printed on paper at the same time as the labels.

22 Enterprise | The Optimization Opty-Way